- vatsaldiam@gmail.com

- +91 88 66 93 3836

Low-pressure, high-temperature (LPHT) annealing of yellow-to-brown type Ia natural diamonds was performed to monitor its effects on optical centers within diamond, changes in the observed color, and to assess the process’s viability as a commercial gem treatment.

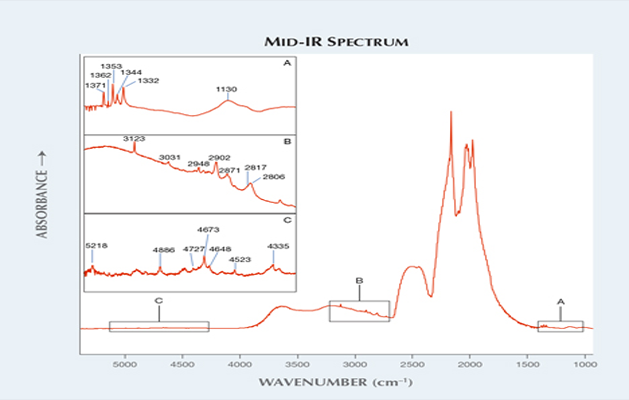

With LPHT annealing only, the mostly brown diamonds showed a shift towards yellow coloration; Vis-NIR absorption spectra showed this change was due to a modest increase in H3 intensity. Even at long annealing times (24 hours at 1800 C) or annealing at high temperatures (2000oC for five minutes), the diamonds did not significantly lose brown coloration. LPHT annealing showed itself as an ineffective means to break apart the vacancy clusters causing the brown color or causing nitrogen disaggregation, which resulted in only a small H3 generation With LPHT annealing, “amber centers” — a group of several independent bands in the IR between 4200 and 4000 cm-1 that disappear with HPHT annealing — were seen to anneal out gradually at various temperatures from 1700–2000 C. In contrast, high-pressure, high-temperature (HPHT) annealing effectively removes brown color at similar time/temperature conditions. Without the high stabilizing pressure provided by HPHT annealing techniques, the LPHT annealing showed pronounced damage on inclusions and dramatic surface etching.

In subsequent experiments, LPHT annealing was used as a follow-up to laboratory irradiation. The irradiation-related vacancies created greater concentrations of H3 and the vacancy-assisted disaggregation of nitrogen created donors which led to a high concentration of H2 centers. This combination of defects resulted in a pronounced and favorable shift towards saleable yellow colors due to an increase in H3 and a dramatic increase in the H2 center, which led to the suppression of the remaining brownish component. The annealing characteristics for many centers detected by Vis-NIR absorption spectroscopy, FTIR absorption spectroscopy, and photoluminescence spectroscopy were chronicled throughout the study and compared with other LPHT annealing studies and HPHT annealing experiments.

Definitely one of the best in diamond industry. Truly a market leader. Vatsal a huge family & they deliver their work in time limits along with excellence in every stage. Highly recommended for diamond processing services & all the other work they provide.

We like Vatsal Diam working culture we have take service of this group , they treat like a friend and they suggest good think about our diamond they have lots of knowledge about diamonds processing work.

Vatsal is the best job work company ever. In all process Vatsal Diam doing best, fastest service ever as well as there is no difficulty to access their work and contacts.