- vatsaldiam@gmail.com

- +91 88 66 93 3836

Diamond like carbon can be removed by a unique process developed by us which removes the excess DLC layer surrounding the rough CVD diamond.

Placement of parts in a planetary fixture using single-, double- or triple-axis rotation

Pump-down under vacuum

Low-temperature preheating process

Ion Bombardment

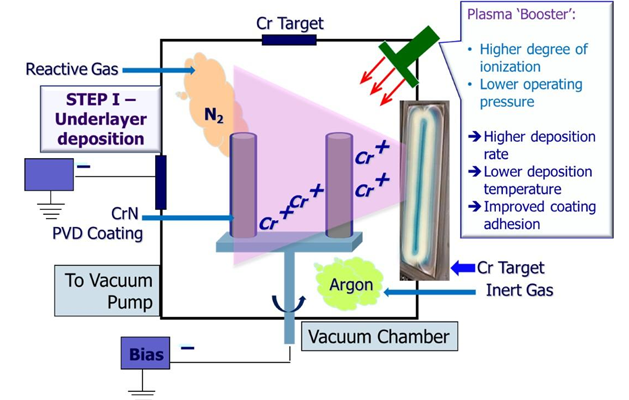

Underlayer deposition (PVD process)

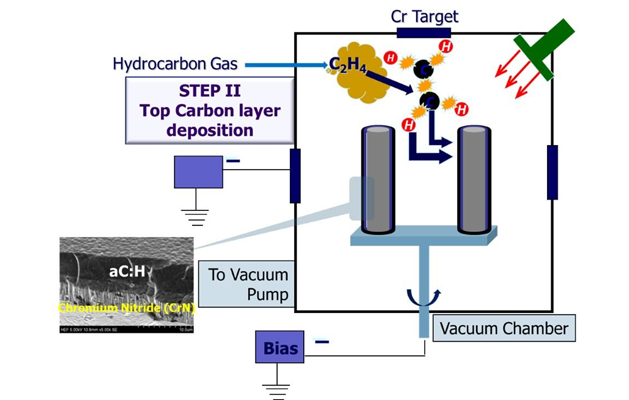

Amorphous carbon layer deposition

Cooling

After going through a multistep pre-cleaning process, the parts are placed on a planetary fixture capable of single, double or triple-axis rotation. The planetary fixture is then placed into the vacuum chamber and the chamber is evacuated and put under vacuum.

After the chamber reaches the preset vacuum level, low-temperature preheating begins. Next the product is bombarded with ions of argon gas to scrub or sputter-clean the surface and remove micro-oxides and micro-contamination. This scrubbing of the surface improves the adhesion of the coating to the substrate.

The first step in the coating process is to deposit an underlayer using a high-energy PVD sputtering process developed by the HEF Group to deposit a dense, well adhered, smooth under layer.

The DLC coatings will usually include several layers of different materials as an underlayer, such as Cr, CrN, W, WC-C or Si, with a top layer of amorphous carbon, with hydrogen. The selection of the underlayer is based upon several factors, such as: adhesion requirements, wear and contact modes, friction regimes encountered during operation, load-carrying capacity, and other metallurgical considerations.

As the underlayer coating reaches the proper thickness, the process transitions into the DLC coating step which deposits a dense, smooth, amorphous carbon hydrogenated (a-C:H) layer onto the product’s surface. The amorphous carbon DLC layer has the unique combination of high hardness and low friction coefficient, yielding the hardness of diamond and the lubricity of graphite. The properties can be tailored to an application depending on:

Deposition technology & parameters

Alloying elements

Coating architecture (single, multilayered, or graded)

In laser process along with DLC process the good part is also cut, while in our DLC remove process this good part can be saved.

This process takes less time than the laser process.

After this process, galaxy and planning can be done easily.

This process increases the yield of polish by 2% to 3%.

The chance of loss in the laser process is 5 to 10%, whereas in this process there is no chance of loss.

Fast delivery will be available in this process.

Definitely one of the best in diamond industry. Truly a market leader. Vatsal a huge family & they deliver their work in time limits along with excellence in every stage. Highly recommended for diamond processing services & all the other work they provide.

We like Vatsal Diam working culture we have take service of this group , they treat like a friend and they suggest good think about our diamond they have lots of knowledge about diamonds processing work.

Vatsal is the best job work company ever. In all process Vatsal Diam doing best, fastest service ever as well as there is no difficulty to access their work and contacts.