- vatsaldiam@gmail.com

- +91 88 66 93 3836

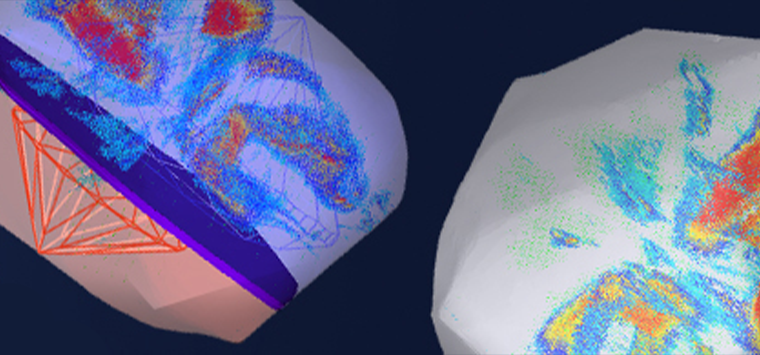

This process helps in reducing the stress (Tension) from the CVD diamond block. The damage caused to the CVD diamonds during shaping, laser sawing, and polishing can be reduced by the Tension removal process.

Special process or very small diamonds at very low cost.

CVD diamonds that size from 3+ to 13- (Diamond Sorting Sieve) round and fancy shapes (Below 0.10ct) are processed with low pressure and low temperature to remove the brown colour and improve the grade of the diamond easily by 2-3 Grades.

The internal structure of a diamond includes areas of physical stress, or tension. These areas develop naturally as the diamond forms. Tension within a diamond can be mild, moderate or extreme. The tension areas cannot be seen by the naked eye, yet they are a real source of stress to diamond cutters and manufacturers.

Procedure:

Examine the Setting:

Protect the Diamond:

Inspect Tension Points:

Release Tension Gradually:

Rotate and Test:

Professional Assistance (Optional):

Inspect After Removal:

Definitely one of the best in diamond industry. Truly a market leader. Vatsal a huge family & they deliver their work in time limits along with excellence in every stage. Highly recommended for diamond processing services & all the other work they provide.

We like Vatsal Diam working culture we have take service of this group , they treat like a friend and they suggest good think about our diamond they have lots of knowledge about diamonds processing work.

Vatsal is the best job work company ever. In all process Vatsal Diam doing best, fastest service ever as well as there is no difficulty to access their work and contacts.